The Problem

Manufacturing teams are drowning in data but starving for insights

- Reactive operations - You find out about problems after they happen

- Disconnected systems - Data trapped in silos across machines and departments

- Manual reporting - Hours spent compiling spreadsheets instead of solving problems

- Hidden inefficiencies - No visibility into true OEE or root causes of losses

The Solution

FluxAI brings intelligence to your manufacturing operations

Real-Time Visibility

See what's happening on every machine, right now. No more walking the floor or waiting for shift reports.

AI-Powered Predictions

Know about problems before they happen. Our AI models learn your equipment and predict failures, quality issues, and performance degradation.

Automated Insights

Stop searching for answers. FluxAI automatically surfaces anomalies, trends, and opportunities you'd otherwise miss.

One Platform

Connect all your machines - old and new - into a single source of truth accessible to everyone who needs it.

Capability 1: Data Collection & Integration

- Connect to PLCs (Siemens, Allen-Bradley, Mitsubishi, and more)

- OPC-UA, Modbus, MQTT protocols

- Sensor integration (vibration, temperature, pressure)

- Works with legacy equipment

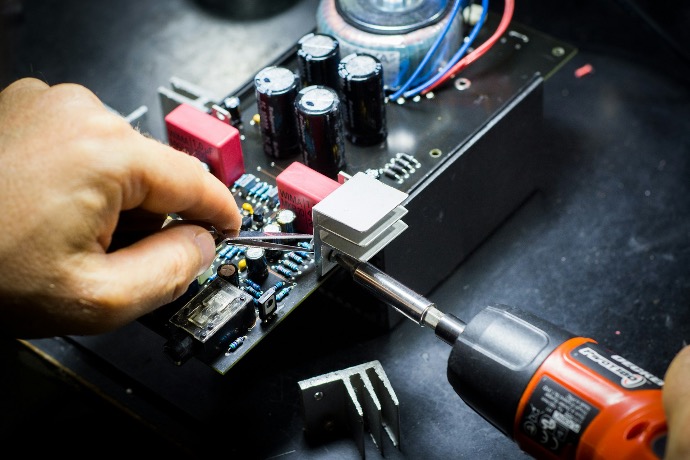

Capability 2: Hardware & Automation

- AI vision cameras for quality inspection

- Industrial sensors and IoT devices

- Edge computing devices

- Relays, I/O modules, and controllers

- Conveyor systems and automation equipment

- Complete turnkey solutions available

Capability 3:

Real-Time Dashboards

- Role-based views (Operator, Supervisor, Manager)

- Live OEE tracking

- Downtime monitoring with reason codes

- Quality metrics and SPC charts

Capability 4:

AI & Analytics

- Predictive maintenance alerts

- Anomaly detection

- Production forecasting

- Root cause analysis

How It Works

1. Connect - Edge device connects to your machines via standard protocols

2. Collect - Data captured in real-time, processed locally

3. Analyze - AI models identify patterns, predict issues

4. Act - Insights delivered to the right people at the right time

Industries

Automotive Manufacturing

- Press shop monitoring

- Assembly line OEE

- Quality traceability

Electronics Manufacturing

- SMT line monitoring

- Connector assembly

- Vision-based inspection

Precision Manufacturing

- CNC machine monitoring

- Tool wear prediction

- Dimensional quality tracking

Process Manufacturing

- Batch monitoring

- Recipe adherence

- Energy optimization

Results

Our customers typically see:

| Metric | Improvement |

|---|---|

| OEE | +10-15% |

| Unplanned Downtime | -30-50% |

| Quality Defects | -20-40% |

| Energy Consumption | -5-15% |

Deployment

Fast Implementation

- 2-4 weeks typical deployment

- Minimal disruption to operations

- No changes to existing equipment

Flexible Architecture

- Edge + Cloud hybrid

- On-premise option available

- Works with or without internet

Secure by Design

- Data encrypted in transit and at rest

- Role-based access control

- Your data stays yours

Pricing

FluxAI is licensed per Monitoring Point with a perpetual license model.

What's a Monitoring Point? A discrete unit of production where FluxAI provides intelligence—whether a single machine, a production line, or an inspection station.

Pricing Components:

- Platform License — One-time base fee for FluxAI access

- Per Monitoring Point — One-time fee for each point you monitor

- Hardware — Cameras, sensors, edge devices (as needed)

- Implementation — Setup, integration, training

- AMC — Annual support, updates, AI model maintenance

Get Started

Ready to bring intelligence to your manufacturing?

Schedule a Demo See FluxAI in action with your use case.

Pilot Program Start with one machine, expand when you're ready.

Legal

--

FluxAI is a product of Trinesis Technologies Private Limited